plug flow reactor solved problems pdf

3If there is zero conversion at the entry to the PFR and 60 at the exit. The stoichiometry of the reaction is 2A R S.

Pdf A Plug Flow Reactor For Studying Fuel Autoignition Chemistry At Pressures Of Up To 50 Bar

What space-time is required to effect this conversion in a plug flow reactor and in a mixed flow reactor.

. 1-11 Strategy to Solve This Problem The solution to this problem requires an analysis of multiple gas-phase reactions in a differential plug-flow tubular reactor. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR. V v 0 B.

Reactor Sizing Reactor Sizing Given r A as a function of conversion -r A fX one can size any type of reactor. This implies for example that if a 20-m reactor of fixed diameter is required to achieve a given conversion the same conversion and capacity can be achieved by running. Completely Mixed Flow Reactor CMFR C.

Consider the following statements. General Mole Balance Equation GMBE 2. Continuous Flow Reactors 33.

Reactors are usually designed based on rate considerations. For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a. For F A0 -r A vs.

Isothermal adiabatic polytropic a cooled or heated reactor in which temperature varies over time or by location. The phrase plug flow profile indicates that there is uniform velocity with no radial variation but. Two different solution strategies are.

Problem Analysis This problem is straightforward. Ideal tubular reactors exhibit plug flow. Tm Tmo for countercurrent flow D and G du dz dp dz F 0 E G ρu - mass velocity P pressure z V A - axial distance u Q A - velocity A cross sectional reactor area F frictional losses Equation E is the momentum balance.

There are some situations where a transient. We are told the reactor is tubular with axial dispersion and to use. DC dt r C Position in a PFR is equivalent to time in a batch reactor x C.

CHEMICAL REACTORS - PROBLEMS OF PLUG FLOW REACTOR 23-35 23-Data from the following table were obtained for the gas phase decomposition of reactant A in a constant volume batch reactor at 100C fed with pure A. F A F A0 1 X Liquidconstantflowrate A. What is the conversion.

Both PFR and BR. We are told the reactor is tubular with axial dispersion and to use. Problem Analysis This problem is straightforward.

Steady State Two types of problems. David Reckhow CEE 370 L9 5. Plug Flow Reactor PFR B.

Stoichiometry relate concentration to volume and number of moles for batch reactors or to volumetric flow rate and molar flow rate for flow reactor. Batch reactor design pdf. In addition you need an initial condition to go with Eq.

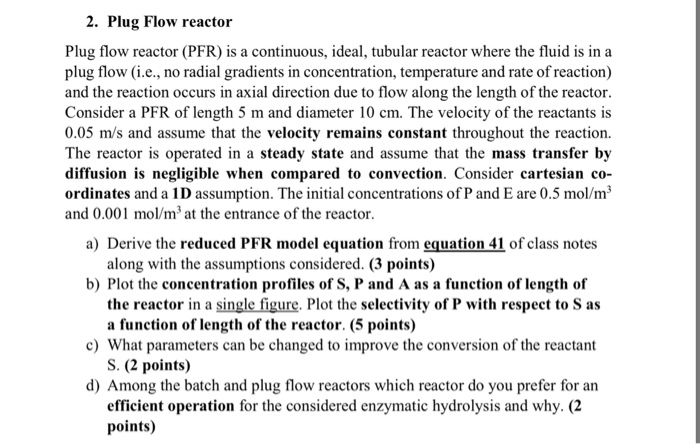

Strictly speaking most real reactors belong in this category. The reactor itself may consist of an empty. Design of Ideal Reactors Plug-flow reactor PFR A plug-flow reactor PFR may be used for both liquid-phase and gas-phase reactions and for both laboratory-scale investigations of kinetics and large-scale production.

NONISOTHERMAL OPERATION OF IDEAL REACTORS Plug Flow Reactor To F jo Q o T F j T mQ mT T o T m mo Assumptions. Calculate the size of the plug flow reactor operating at 100C and 1. Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant.

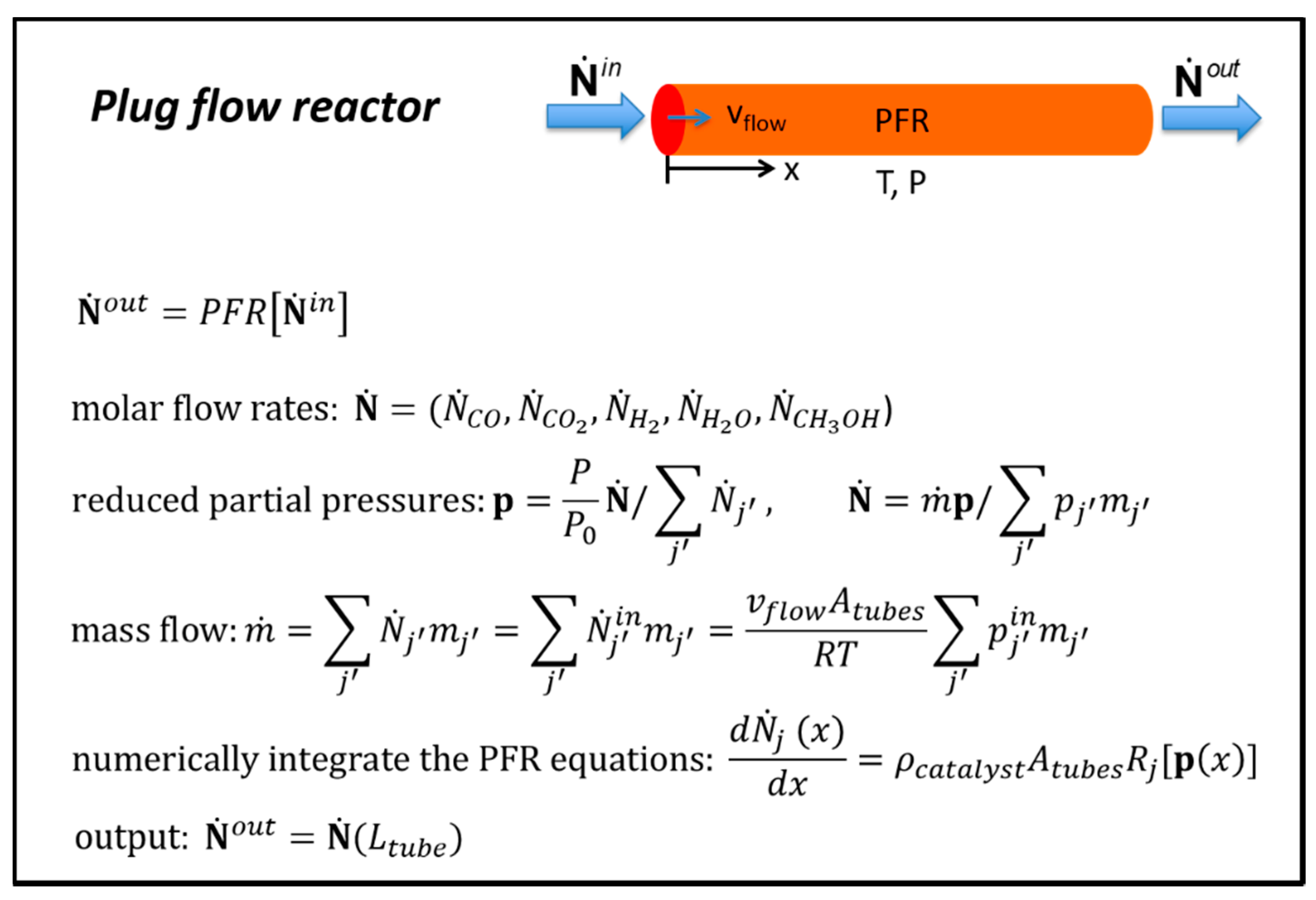

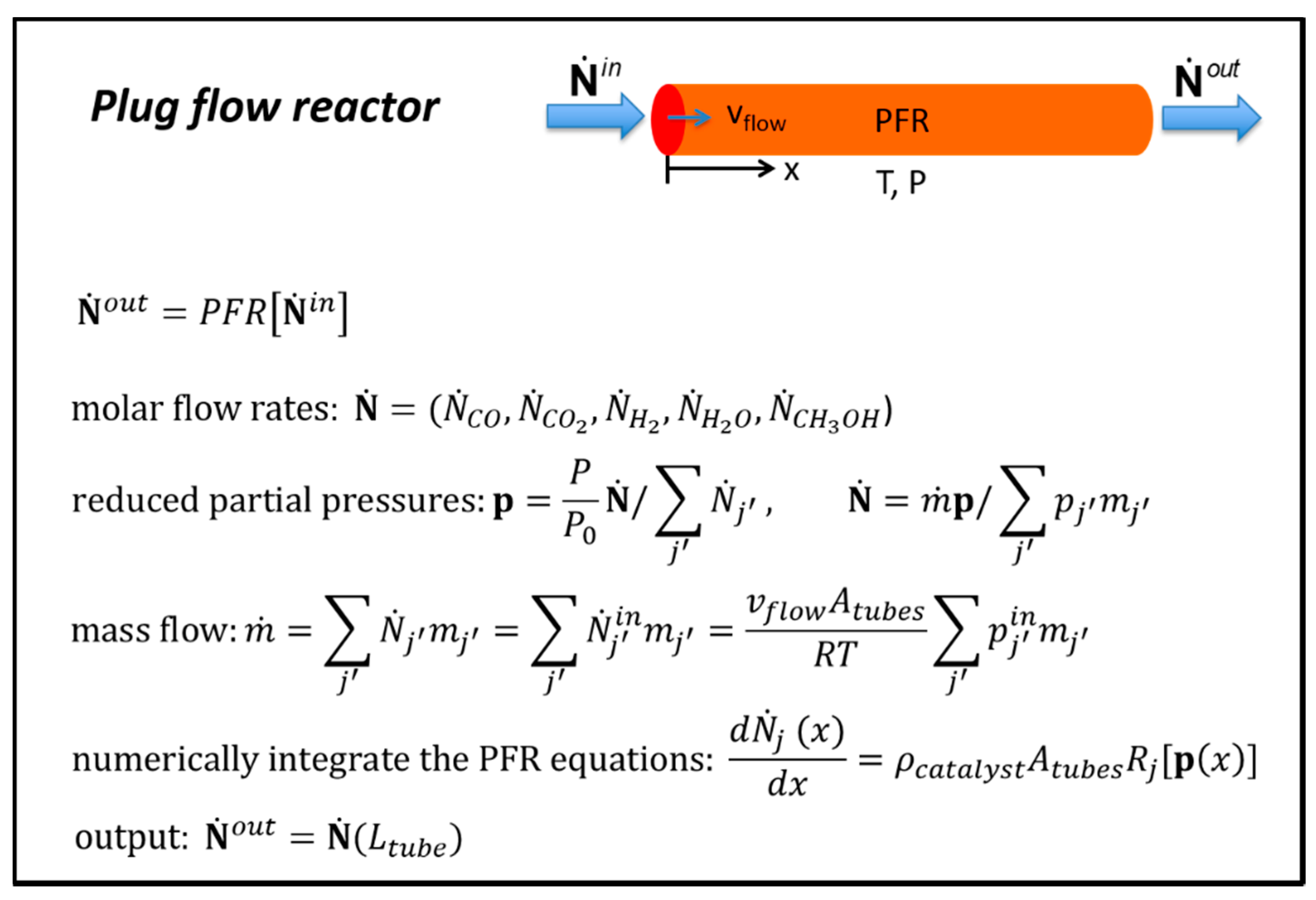

The concentration of species and the temperature inside the PFR can vary with time t axial position z. Many chemicals are involved and you need a reaction rate for each reaction occurring. Plug Flow Reactor PFR The third general type of reactor is the Plug Flow Reactor PFR.

In Chapter 2 governing equations for the plug flow reactor are first summarized for reference. Compare a plot of the conversion versus length to that for a plug flow reactor for reactor lengths from zero to fifty times the particle diameter. Clearly state all assumptions used in your derivation.

Depends on the reaction order E. Chapter 3 discusses the mechanics of actually running the program and pre-processors and then Chapter 4 discusses the keyword input used in specifying the problem to be solved. The structure of the problem is the same as that for a plug flow reactor and if one can solve one one can solve the other.

The main assumptions of this model are that the fluid is completely mixed in any cross-section at any point but it experiences no axial mixing ie. Based on heat transfer reactors can be classified as. So there is some economy of effort.

Here we plot either F A0 -r A or 1 -r A as a function of X. David Reckhow CEE 370 L9 4 Brominated DBPs. Batch Reactor BR D.

DC d r C Ideal batch. The reaction 𝐴𝐴 𝑅𝑅 is first order on reactant A. Given desired production rate conversion and kinetics and other parameters determine the required reactor size heat duty and temperature profile.

Compare ideal batch and ideal PFR mass balances. You will learn how to formulate models for transient PFRs though. Based on the number of phases reactorsreactions can categorized as.

The reaction occurs along the flow path. 2Assuming these assumptions are all met calculate the plug flow reactors volume to achieve a 60 conversion given a feed rate of 15mols 1 to the reactor. 11 ct 0 c0.

IIIC3ai Plug flow reactors. X the volume of a CSTR and the volume of a PFR can be represented. Reactants are fed in one end of the pipe and some mixture of reactants and products emerge from the far end.

C A F A v ii. Problem 2 In an isothermal batch reactor 70 of a liquid reactant is converted in 13 minutes. A plug flow reactor PFR is a pipe.

The reactor contains a fixed bed of 0004 m diameter catalyst particles. Debasree Ghosh Lecture notes on Polymer Reaction Engineering Module II. Plug flow reactors volume.

Contiguous cross-sections cannot exchange mass with each other. The system may be either contained as in a water main oil pipeline or blood vessel or open as in a. We do this by constructing a Levenspiel Plot.

A Plug Flow Reactor PFR consists in a long straight pipe in which the reactive fluid transits at steady-state no accumulation. The reaction 𝐴𝐴 𝑅𝑅 is first order on reactant A. What space-time is required to effect this conversion in a plug flow reactor and in a mixed flow reactor.

However this equation is usually solved separately and a mean. Two commonly used reactors are the CSTR continuous stirred tank reactor and the PFR plug flow reactor. The reaction is second-order with respect to A and the volume of the plug flow unit is three times that of the mixed flow unit.

Problem 2 In an isothermal batch reactor 70 of a liquid reactant is converted in 13 minutes. Your answer by calculating the reactor volume in liters and the outlet molar flow rate of triethanolamine that correspond to your design. Chapter 5 discusses post-processing options.

These reactors provide enough residence time for the reaction to take place with satisfactory conversion. Rate Laws Write down rate law in terms of limiting reactant. Plug flow reactor solved problems pdf.

In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug. Transient plug flow reactor problems that require the use of equations 271 and 272 will not be solved in this course but their solution will be described without going into the numerical details. General Algorithm for Solving Isothermal Reactor Problems.

Consider the following statements.

Chemical Reactors Problems Of Plug Flow Reactor 23 35 4c2h2

Solved 4 You Are Designing A Reactor That Uses Chlorine In A Pfr Or Cstr 1 Answer Transtutors

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

2 Plug Flow Reactor Plug Flow Reactor Pfr Is A Chegg Com

Matlab In Chemical Engineering At Cmu

Pdf Plug Flow Reactor Model Wikipedia The Free Encyclopedia Praveenkumar Dtv Academia Edu